MANUFACTURING SERVICES

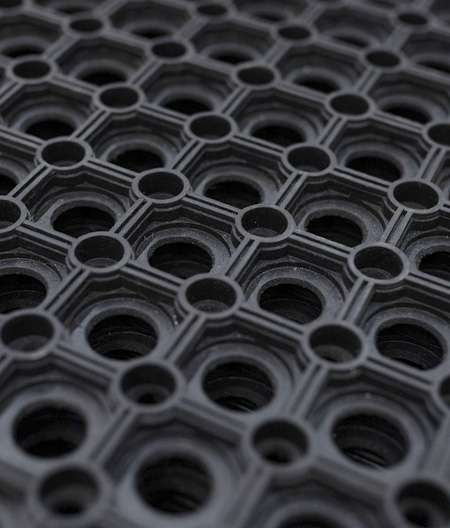

ProtoEdge provides a comprehensive manufacturing solution that caters to your low-to-mid-volume production and prototyping needs. For high-end-quality solutions that meet your exact specifications, services include CNC machining, 3D printing, injection molding, rubber molding, and sheet metal fabrication plus more turnkey methods. You can have peace of mind that your manufacturing requirements will be handled efficiently and effectively. Delivering the entire solution for a seamless manufacturing experience that meets all your needs.

ProtoEdge is well-versed in producing parts and assemblies for various industries. Our people are knowledgeable about the specific requirements each sector demands in terms of production quality and material selection. Our capabilities range from short to long-run requirements, allowing us to provide effective solutions with the right people and equipment.

The industries that we serve include:

- Aerospace

- Automation

- Automotive

- Computers

- Medical

- Industrial

- Robotics

We commonly manufacture parts using different technology processes which can help speed up your product development process. Also, reduce your supply chain backlog for custom parts and make sure that you receive the required parts promptly. We deliver exceptional services in digital manufacturing which allows you to produce low-volume parts and prototypes with high performance quickly and easily. We are committed to quality processes throughout our precision parts manufacturer operation.

CUSTOM PARTS & PROTOTYPES

In any product development process, custom parts and prototypes are crucial. They enable engineers to test their designs and identify potential problems before mass production. ProtoEdge offers various manufacturing methods tailored to your specific project needs.

CNC machining is an excellent option for low to mid-volume production or prototypes requiring high accuracy and precision. Injection molding is suitable for low to mid-volume production or parts requiring high volumes. 3D printing is ideal for quick and less expensive prototypes.

Common

Applications

- Ability to test part designs

- Biuld functional prototypes

- Validate products design build early in the development process

- Manage quantity volatility

- Reduce design risk

- Test multiple designs iterations

- Using digital technologies to bring parts to market faster

LOW VOLUME MANUFACTURING

Partnering with a manufacturing specialist saves time in all processes from low-volume production and prototypes. Product development, with expert engineering support, speeds the design and development process. Outsourcing increases a company’s capability without incurring expensive equipment and tools. We manufacture a diverse range of products, from parts to complex assemblies. ProtoEdge volumes can range from 1 to 75,000 units, and we can deliver within 2 to 4 weeks, depending on the requested geometry and accuracy for repeatability. We take great pride in maintaining high-quality processes throughout our precision parts manufacturing operations, and our manufacturing network is certified with both ISO 9001:2015 and ISO 2768. We are proud to partner as a supplier of top-quality manufacturing services and components to vital industries.

Our service can be of value to your company with optimum efficiency with end-use-low-volume finished parts, prototypes, sales samples, engineering evaluation samples, and fixtures. Contact us to learn more about how we can help you with your next project.

.jpg)